Materials

Alloys

- Stainless Steel

- Brass

- Monel

- Hastelloy

- Titanium

- Product Coating / Finishes

- Perforation

- Wire Mesh

MATERIAL |

UNS/SPEC #s |

DESCRIPTION/APPLICATIONS |

BASIC COMPOSITION % |

FORMS |

ALLOY |

UNS S30400 |

|

18.0/20.0 Cr 8.0/11.0 Ni 0.08 Max C Bal Fe |

PIPE-TUBE FITTINGS FLANGES BAR-SHAPES SHEET PLATES |

ALLOY |

UNS S30403 |

|

18.0/20.0 Cr 8.0/13.0 Ni 0.035 MaxC Bal Fe |

PIPE-TUBE FITIINGS FLANGES BAR-SHEET SHEET PLATE |

ALLOY |

UNS S31600 ASTM A- |

|

16.0/18.0 Cr 10.0/14.0 Ni 2.0/3.0 Mo 0.08 Max C Bal Fe |

PIPE-TUBE FITTINGS FLANGES BAR-SHAPES SHEET PLATES |

ALLOY |

UNS S31603 ASTM A- |

|

16.0118.0 Cr 10.0/14.0 Ni 2.0/3.0Mo 0.035MaxC Bal Fe |

PIPE-TUBE FITTINGS FLANGES BAR-SHAPES SHEET PLATE |

Applications

260 Brass has a wide range of applications, such as appliance parts, highly formable parts, ammunition components, decorative parts of furniture and cabinets, name plates, engraving plates, overlays, legend plates, lamp fixtures, fasteners, locks, hinges, flashlight shells, connectors, fittings, circuit board relays, electronic components, switches, nuts, bolts, valve stems and valve components, radiator cores and tanks, brackets, frames, fixtures, ornamental works, and used extensively in the musical instrument, electrical equipment, plumbing, central heating, seawater lines and desalination fields.

Machineability and Weldability

In its half-hard condition, 260 Brass has a machinability rating of 30 as compared to 360 brass rated at 100. 260 Brass has the highest ductility in the yellow brass series. Welding is not recommended, although 260 Brass has low to fair soldering and brazing capabilities. 260 Brass has poor butt-welding characteristics.

Material Overview

Characteristics: Monel is a high tensile strength nickel-copper alloy that was discovered in 1905. It was found to be highly resistant to atmospheric corrosion, salt water, and various acid and alkaline solutions. Alloy 400 can be magnetic depending upon composition and previous work history. Alloy K-500 has added aluminum and titanium for age hardening. It is totally nonmagnetic and spark resistant.

Uses: K-500 is used for gyroscope application and anchor cable aboard minesweepers. It is also used for propeller shafts on a wide variety of vessels and exhibits high fatigue strength in seawater. There is also application in chemical process applications for handling of organic acids, caustic and dry chlorine.

Monel 400 is used for marine engineering, chemical and hydrocarbon processing equipment, valves, pumps, shafts, fittings, fasteners, and heat exchangers.

General Properties

|

Typical Mechanical Properties |

||||||||||||||

Limiting Chemical Composition, % Nia - 63.0 min. |

Typical Mechanical Properties (Annealed) Tensile Strength, psi •••••• 80,000 |

||||||||||||||

Physical Constants and Thermal Properties Density, Ib/in3 •••••• 0.318 |

Specifications and Designation UNS N04400 |

||||||||||||||

Hastelloy® C-276

UNS Number N10276

Other common names: Alloy C276, Hastelloy C, Inconel® C-276

Hastelloy C276 is a nickel-molybdenum-chromium superalloy with an addition of tungsten designed to have excellent corrosion resistance in a wide range of severe environments. The high nickel and molybdenum contents make the nickel steel alloy especially resistant to pitting and crevice corrosion in reducing environments while chromium conveys resistance to oxidizing media. The low carbon content minimizes carbide precipitation during welding to maintain corrosion resistance in as-welded structures. This nickel alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process application in an as welded condition.

Although there are several variations of the Hastelloy nickel alloy, Hastelloy C-276 is by far the most widely used.

Alloy C-276 is widely used in the most severe environments such as chemical processing, pollution control, pulp and paper production, industrial and municipal waste treatment, and recovery of sour natural gas.

Corrosion Resistant Hastelloy C276

Considered one of the most versatile corrosion resistant alloys available, Hastelloy C-276 exhibits excellent resistance in a wide variety of chemical process environments including those with ferric and cupric chlorides, hot contaminated organic and inorganic media, chlorine, formic and acetic acids, acetic anhydride, seawater, brine and hypochlorite and chlorine dioxide solutions. In addition, alloy C-276 resists formation of grain boundary precipitates in the weld heat affected zone making it useful for most chemical processes in the as-welded condition. This alloy has excellent resistance to pitting and stress corrosion cracking.

What are the characteristics of Hastelloy C276?

- Excellent corrosion resistance in reducing environments

- Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

- High nickel and molybdenum contents providing good corrosion resistance in reducing environments

- Low carbon content which minimizes grain-boundary carbide precipitation during welding to maintain resistance to corrosion in heat-affected zones of welded joints

- Resistance to localized corrosion such as pitting and stress-corrosion cracking

- One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

Chemical Composition, %

Ni |

Mo | Cr | Fe | W | Co | Mn | C |

|---|---|---|---|---|---|---|---|

| Remainder | 15.0-17.0 | 14.5-16.5 | 4.0-7.0 | 3.0-4.5 | 2.5 max | 1.0 max | .01 max |

V |

P | S | Si | ||||

| .35 max | .04 max | .03 max | .08 max |

In what applications is Hastelloy C-276 used?

- Pollution control stack liners, ducts, dampers, scrubbers, stack-gas reheaters, fans and fan housings

- Flue gas desulfurization systems

- Chemical processing components like heat exchangers, reaction vessels, evaporators, and transfer piping

- Sour gas wells

- Pulp and paper production

- Waste treatment

- Pharmaceutical and food processing equipment

History of Titanium

Originally named gregorite, after the British chemist, Reverend William Gregor who discovered it in 1791, titanium was independently discovered by the German chemist M.H. Klaproth in 1793. He named it Titanium after the Titans of Greek mythology; “the incarnation of natural strength.” In 1797 he discovered that his titanium was the same as Gregor’s newly found element. However, the element was not successfully isolated until 1910.

Titanium is the 22nd element on the periodic table. Its atomic weight is 47.867amu. It is a low density element (4510 kg/m3); approximately 60% less dense than that that of steel. It is nonmagnetic, and transfers heat well. Its melting point (1993 K [3020 degrees F and 1650 degrees C]) is also higher than that of steel. Titanium has high passivity; therefore it exhibits high levels of corrosion resistance to most mineral acids and chlorides. It is also nontoxic and biologically compatible with human tissue and bone, making it an ideal material for medical implant products.

Rutile and ilmenite, the 2 primary minerals which contain titanium, make up 24% of the earth’s crust, thus making titanium the ninth most abundant element on the planet. However, it occurs in nature only in chemical combinations; the most common of which are oxygen and iron.

Properties of Titanium

|

|

Coating and Finishes

We offer a variety of coating and finishes for our products such as Halar, Tefzel, Teflon, Electropolishing and Passivation.

|

|

|

|

|

||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

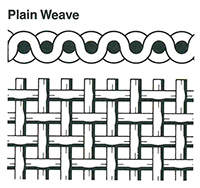

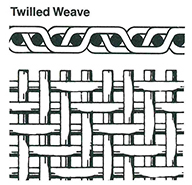

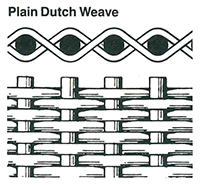

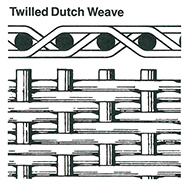

Wire Mesh

Accomplish the finest Filtration with our screen baskets. These baskets are specifically designed to meet requirements, whereby absolute purification is critical. Fluid Filtration Manufacturing Corp. can incorporate its regular perforated sheet metal baskets with finer commercial grade wire cloth to achieve the ultimate filtration. In addition, we can increase these baskets potential with our magnet insertion, therefore doubling their filtering abilities. Our mesh screen baskets can be constructed from various wire cloths. Please refer to table for mesh size.

Mesh Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Mesh Technical Data |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Material available are Monel, Phosphor Bronze, and Stainless Steel. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||