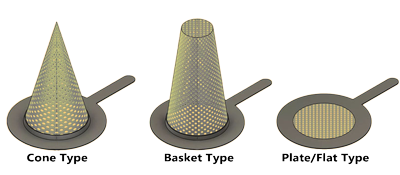

Temporary Cone, Basket, and Plate/Flat type Strainers

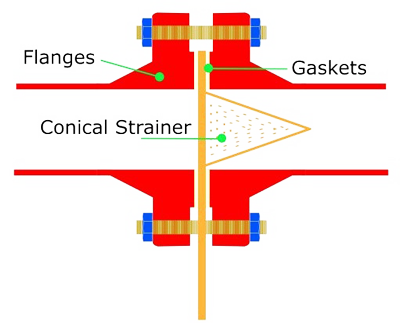

Temporary Strainer

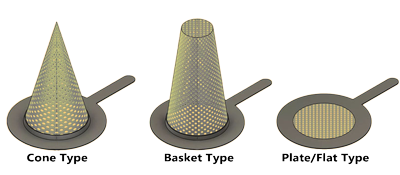

Temporary strainer is a startup strainer, also known as conical strainer or basket strainer, and is installed in a system to remove unwanted debris from the process stream. These strainers come in cone as well as basket shape along with plate strainers.

Where Used..?

Where Used..?

Temporary strainer is installed to protect a flow meter, pump, control or relief valves or other pieces of equipment during startup.

During construction, materials may become trapped in the line. These materials could be welding slag, welding rod, pieces of wood, cigarettes, rocks, etc. Many pieces of equipment will become damaged if this debris enters it. After start up is completed, the startup strainer should be removed.

Materials of Construction

Materials of construction of a strainer should be compatible with the fluid. Most commonly used materials of construction are :

-

Stainless Steel : 304, 306 etc.

- Monel Metal

Dimensional Standards

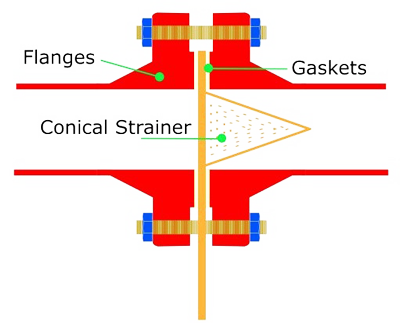

Dimensions of conical strainers are manufacturer specific. Main disc of conical strainers is made to fit between flanges of rating as per main pipe specification.

Design Requirements

1. If a strainer cannot withstand high temperatures or differential pressures, it could come apart and cause damage to equipment.

2.

The expected pressure drop across the strainer should not cause the downstream operating pressure to fall below the minimum required pressure of the line e.g. NPSH for a pump.

3.

The perforations of the strainer should be slightly smaller than the smallest piece of debris that is expected to flow through it.

4.

If the perforations are too small, a high pressure drop could develop across the strainer and cause it to fail.

Installation in Piping

1. Strainer should be easily removed by adding a pipe support or pipe stand close to the strainer and/ or a removable spool so that the strainer can be removed easily.

2.

It should be possible to remove the temporary strainer without shutting down the process with the help of a redundant piece of equipment that can be used while the strainer is being removed, or with block valves to allow bypass the strainer.

Strainer plate thickness considerations

1. A the flange, the temporary strainer is usually 1/16” thick and it also requires two gaskets.

2.

When the strainer is removed, it must be decided how will the pipe be connected again without double or triple stacking gaskets.

3. Spacer can be used in place of temporary strainer based on company policy.

4.

A temporary strainer can add 1/8” to the length of the bolts.

5.

Some companies require full thread engagement when installing piping and the extra 1/8” can be added to the bolt size.

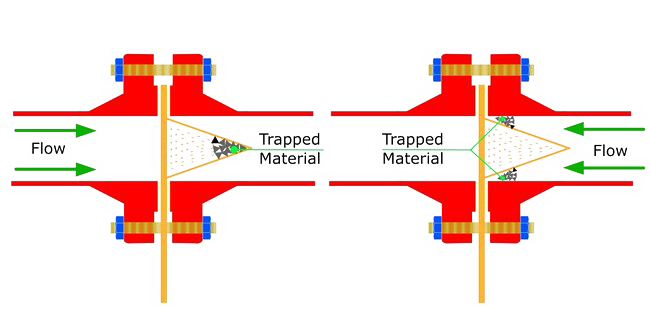

Cone direction upstream or downstream..?

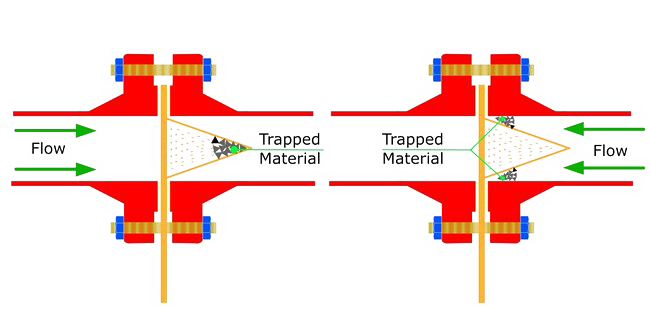

1. Installation of a conical strainer can be done in one of two different ways, cone facing upstream or cone facing downstream.

2.

When cone is downstream, debris collects inside of the cone near the tip and cone may rip apart due to heavy strain on the tip.

3.

Advantage of cone downstream side is easier removal of debris. But mechanical strength of cone shall be ensured.

4.

When cone is upstream, debris collects to the side of the strainer. Its advantage is that any plugging of the strainer will start in the outside and work its way in.

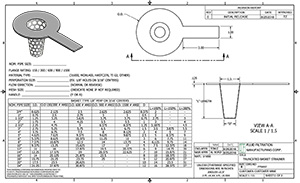

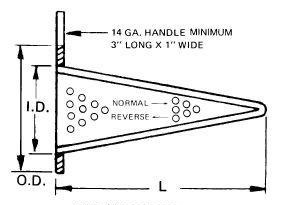

- Cone Type

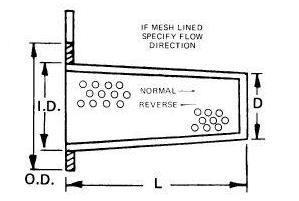

- Basket Type

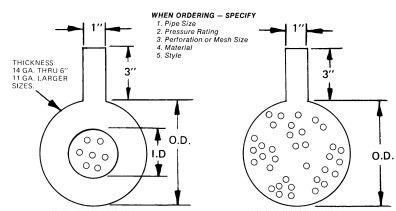

- Plate/Flat Type

- Ring & Flange Finish

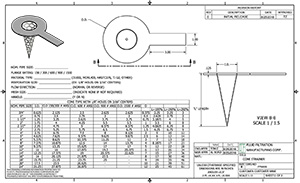

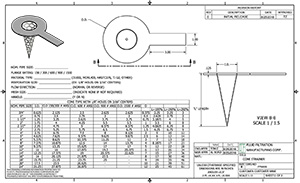

Click above to preview drawing |

- Conical & Basket strainers are designed to provide protection for expensive pumps, valves, meters and other mechanical equipments from foreign objects. They are installed between flanges and work as a temporary or permanent filtering devices.

- Normally supplied with 1/8" dia. holes on 3/16" centers (available in most sizes with perforations & mesh).

- Carbon steel, stainless steel and other alloys available.

- For ring type joint- specify ring number & style.

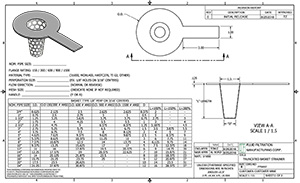

- When ordering, the following information should be specified: 1) Pipe size, 2) Pressure rating, 3) Perforation or mesh size, 4) Material, 5) Style.

- Contact our engineering department for special designs or length.

Cone Strainer Cone Strainer SIZE 12"-600# DOUBLE ELEMENT CONE MESH LINED FOR NORMAL FLOW SIZE 12"-600# DOUBLE ELEMENT CONE MESH LINED FOR NORMAL FLOW

|

|

Dimension: Style B-With 1/8" D. Holes on 3/16 Centers

| Nominal Pipe Size |

I.D. |

150/300 # ANSI

(O.D.) |

600 # ANSI

(O.D.) |

900 # ANSI

(O.D.) |

1500 # ANSI

(O.D.) |

D |

Standard L |

L-150% |

L-200% |

| 3/4 |

5/8 |

2 1/8 |

2 1/2 |

2 5/8 |

2 5/8 |

3/8 |

2 1/4 |

2 1/4 |

3 |

| 1 |

3/4 |

2 1/2 |

2 3/4 |

3 |

3 |

1/2 |

2 5/8 |

2 3/4 |

3 |

| 1 1/2 |

1 1/4 |

3 1/4 |

3 5/8 |

3 3/4 |

3 3/4 |

3/4 |

3 3/16 |

4 |

5 |

| 2 |

1 3/4 |

4 |

4 1/4 |

5 1/2 |

5 1/2 |

1 |

3 1/2 |

6 |

8 |

| 2 1/2 |

2 1/4 |

4 3/4 |

5 |

6 3/8 |

6 3/8 |

1 1/4 |

4 1/16 |

6 1/4 |

8 |

| 3 |

2 3/4 |

5 1/4 |

5 3/4 |

6 1/2 |

6 3/4 |

1 1/2 |

4 1/4 |

6 3/4 |

9 |

| 4 |

3 3/4 |

6 3/4 |

7 1/2 |

8 |

8 1/8 |

2 |

5 |

10 |

12 |

| 5 |

4 5/8 |

7 5/8 |

9 3/8 |

9 5/8 |

9 7/8 |

2 1/2 |

6 |

12 |

14 |

| 6 |

5 3/8 |

8 5/8 |

10 3/8 |

11 1/4 |

11 |

3 |

7 |

13 |

18 |

| 8 |

7 3/8 |

10 7/8 |

12 1/2 |

14 |

13 3/4 |

4 |

8 3/16 |

17 |

23 |

| 10 |

9 3/8 |

13 1/4 |

15 5/8 |

17 |

17 |

5 |

12 |

22 |

28 |

| 12 |

11 |

16 |

17 7/8 |

19 1/2 |

20 3/8 |

6 |

13 |

26 |

34 |

| 14 |

12 1/4 |

17 3/8 |

19 |

20 3/8 |

22 5/8 |

7 |

15 |

27 |

36 |

| 16 |

14 |

20 1/8 |

21 7/8 |

22 1/2 |

- |

8 |

17 |

30 |

40 |

| 18 |

15 3/4 |

21 1/4 |

23 3/4 |

25 |

- |

9 |

19 |

35 |

46 |

| 20 |

17 1/2 |

23 1/2 |

26 5/8 |

- |

- |

10 |

21 |

39 |

51 |

| 24 |

21 1/4 |

27 7/8 |

30 7/8 |

- |

- |

12 |

25 |

45 |

61 |

All dimensions in inches - larger sizes available. |

All Stainless Steel 316 threaded, 1/8 perforated mesh lined cone strainers

Temporary Double Cone Strainers with mesh liner

Titanium perforated cones

Hastelloy C-276 Special Cone Type Strainers

SS316 Cone Type Strainers

RTJ Cone Type 316 Stainless Steel Perforated Witches Hat

Nichrome V Large Mesh Cone Strainers with 32' Bolted Flange

Stainless steel 1/8" perforated heavy duty cone type strainers with mesh liner

Brass/Copper cone strainers

Heavy duty stainless steel 316, 20 x 20 mesh cone type strainers

Zirconium cone type strainers

Cone type flanged strainers

Reverse mesh lined outside cone type strainer

Perforated/Mesh type cone strainers

Size 24.0" cone type strainer with mesh liner outside

Size 20.0" stainless steel 150% open area cone type strainer with mesh liner outside

Hastelloy cone with support ring inside

RTJ and raised faced flanges are available

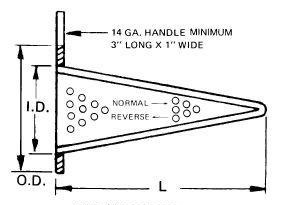

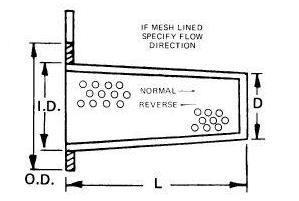

Click above to preview drawing |

- Conical & Basket strainers are designed to provide protection for expensive pumps, valves, meters and other mechanical equipments from foreign objects. They are installed between flanges and work as a temporary or permanent filtering devices.

- Normally supplied with 1/8" dia. holes on 3/16" centers (available in most sizes with perforations & mesh).

- Carbon steel, stainless steel and other alloys available.

- For ring type joint- specify ring number & style.

- When ordering, the following information should be specified: 1) Pipe size, 2) Pressure rating, 3) Perforation or mesh size, 4) Material, 5) Style.

- Contact our engineering department for special designs or length.

Truncated Basket Strainer Truncated Basket Strainer

|

|

Dimension: Style B-With 1/8" D. Holes on 3/16 Centers

Nominal

Pipe

Size |

I.D. |

150/300 # ANSI

(O.D.) |

600 # ANSI

(O.D.) |

900 # ANSI

(O.D.) |

1500 # ANSI

(O.D.) |

D |

Standard L |

L-150% |

L-200% |

| 3/4 |

5/8 |

2 1/8 |

2 1/2 |

2 5/8 |

2 5/8 |

3/8 |

2 |

- |

- |

| 1 |

3/4 |

2 1/2 |

2 3/4 |

3 |

3 |

1/2 |

2 |

- |

- |

| 1 1/2 |

1 1/4 |

3 1/4 |

3 5/8 |

3 3/4 |

3 3/4 |

3/4 |

2 3/4 |

- |

3 |

| 2 |

1 3/4 |

4 |

4 1/4 |

5 1/2 |

5 1/2 |

1 |

3 |

- |

4 |

| 2 1/2 |

2 1/4 |

4 3/4 |

5 |

6 3/8 |

6 3/8 |

1 1/4 |

3 3/16 |

- |

4 1/2 |

| 3 |

2 3/4 |

5 1/4 |

5 3/4 |

6 1/2 |

6 3/4 |

1 1/2 |

3 1/2 |

3 7/8 |

5 1/2 |

| 4 |

3 3/4 |

6 3/4 |

7 1/2 |

8 |

8 1/8 |

2 |

4 |

5 |

7 |

| 5 |

4 5/8 |

7 5/8 |

9 3/8 |

9 5/8 |

9 7/8 |

2 1/2 |

5 |

6 3/8 |

9 |

| 6 |

5 3/8 |

8 5/8 |

10 3/8 |

11 1/4 |

11 |

3 |

6 |

7 3/4 |

11 |

| 8 |

7 3/8 |

10 7/8 |

12 1/2 |

14 |

13 3/4 |

4 |

6 1/8 |

9 3/4 |

14 |

| 10 |

9 3/8 |

13 1/4 |

15 5/8 |

17 |

17 |

5 |

7 1/2 |

12 3/8 |

18 |

| 12 |

11 |

16 |

17 7/8 |

19 1/2 |

20 3/8 |

6 |

9 |

14 3/4 |

20 |

| 14 |

12 1/4 |

17 3/8 |

19 |

20 3/8 |

22 5/8 |

7 |

10 |

15 7/8 |

21 |

| 16 |

14 |

20 1/8 |

21 7/8 |

22 1/2 |

- |

8 |

10 |

18 3/8 |

23 |

| 18 |

15 3/4 |

21 1/4 |

23 3/4 |

25 |

- |

9 |

12 |

20 7/8 |

27 |

| 20 |

17 1/2 |

23 1/2 |

26 5/8 |

- |

- |

10 |

14 |

23 1/2 |

31 |

| 24 |

21 1/4 |

27 7/8 |

30 7/8 |

- |

- |

12 |

16 |

28 3/8 |

37 |

All dimensions in inches - larger sizes available. |

Stainless steel 1/8" perforated heavy duty basket type strainers.

Cone/Truncated tapered Stainless Steel three layer perforated/mesh strainers

All 316 Stainless Steel trancated strainers, 1/32" perforated

2.0" heavy duty temporary basket type strainers with laser cut flanges.

Heavy duty stainless steel 316, 1/8" perforated basket type strainers with removable perforated inner stainless steel inserts.

Truncated//Basket strainers with inner and outer cage.

Truncated mesh line strainers with support hoops on outside and serrated flange.

Ring-Type-Joint Stainless Steel high pressure basket strainers.

Stainless Steel strainers with Ring-Type-Joint for reverse flow

Stainless Steel 150lb flange truncated strainers

Size 20.0"/25.0" truncated basket strainers with mesh lined outside.

Double screen stainless steel 316 truncated strainers.

Heavy duty 316 stainless steel temporary cone basket type straine with double mesh outside for reverse flow. With support rings on outter basket to prevent mesh tears/rips under high pressure with support rings inside.

RTJ and raised faced flanges are available.

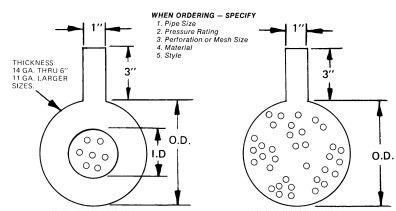

|

- Normally supplied with 1/8" dia. holes on 3/16" centers(available in most sizes with perforations & mesh).

- Carbon steel, stainless steel and other alloys available.

- For ring type joint- specify ring number & style.

- When ordering, the following information should be specified: 1) Pipe size, 2) Pressure rating, 3) Perforation or mesh size, 4) Material, 5) Style.

- Contact our engineering department for special designs or length.

|

|

Dimension 1/8" D. Holes on 3/16" Centers

| Nominal Pipe Size |

I.D. |

150/300 # ANSI

(O.D.) |

600 # ANSI

(O.D.) |

900 # ANSI

(O.D.) |

1500 # ANSI

(O.D.) |

| 3/4 |

3/4 |

2 1/8 |

2 1/2 |

2 5/8 |

2 5/8 |

| 1 |

1 |

2 1/2 |

2 3/4 |

3 |

3 |

| 1 1/2 |

1 1/2 |

3 1/4 |

3 5/8 |

3 3/4 |

3 3/4 |

| 2 |

2 |

4 |

4 1/4 |

5 1/2 |

5 1/2 |

| 2 1/2 |

2 1/2 |

4 3/4 |

5 |

6 3/8 |

6 3/8 |

| 3 |

3 |

5 1/4 |

5 3/4 |

6 1/2 |

6 3/4 |

| 4 |

4 |

6 3/4 |

7 1/2 |

8 |

8 1/8 |

| 5 |

5 |

7 5/8 |

9 3/8 |

9 5/8 |

9 7/8 |

| 6 |

6 |

8 5/8 |

10 3/8 |

11 1/4 |

11 |

| 8 |

8 |

10 7/8 |

12 1/2 |

14 |

13 3/4 |

| 10 |

10 |

13 1/4 |

15 5/8 |

17 |

17 |

| 12 |

12 |

16 |

17 7/8 |

19 1/2 |

20 3/8 |

| 14 |

13 1/4 |

17 3/8 |

19 |

20 3/8 |

22 5/8 |

| 16 |

15 1/4 |

20 1/8 |

21 7/8 |

22 1/2 |

- |

| 18 |

17 1/4 |

21 1/4 |

23 3/4 |

25 |

- |

| 20 |

19 1/4 |

23 1/2 |

26 5/8 |

- |

- |

| 24 |

23 1/4 |

27 7/8 |

30 7/8 |

- |

- |

All dimensions in inches - larger sizes available. |

Stainless steel temporary flat strainers.

|

|

|

MILL FINISH

Some scale and light rust may be apparent. |

MILL POLISH

Standard smooth finish by mill for 304 & 316 grades. |

FACTORY POLISH

A non-concentric, abrasively machined surface with flat, parallel finish. 63-125 AARH. |

|

|

|

SERRATED SPIRAL / SERRATED CONCENTRIC MACHINED

Flange finish to be 125-500 AARH with serrated spiral surface finish. |

RAISED FACED FLANGE

Standard ANSI fange with smooth serrated finish. |

|

|

|

RING TYPE JOINT MALE

Standard finish is smooth machined surface with maximum roughness of 63 AARH. |

RING TYPE JOINT FEMALE

Standard finish is smooth machined surface with maximum roughness of 63 AARH. |

|

All Dimensions Per ASME B16.5

Notes: |

1. |

For use with Flat or Raised Face Flanges |

|

2. |

Standard rings are Factory Polish 63-125 AARH. For any other surface finish, customer must specify. |

|

3. |

Avaialable with Serrated Spiral surface finish and Ring Type Joint |

Where Used..?

Where Used..?